Seems that my typewriter repair skill has made great improvement these days. I saved my Royal 10 today on my own today!

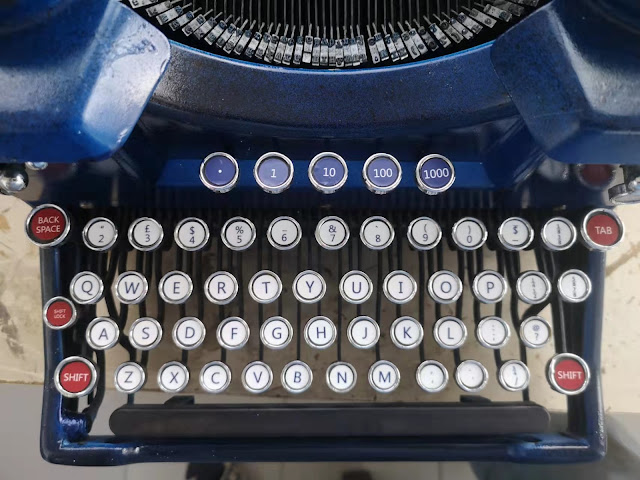

Actually I have had this stately machine for at least 15 years. Man, I simply cannot have enough of Royal 10. They look great and still work great 80 years since they were built. These machines was made to last forever, quite literally!

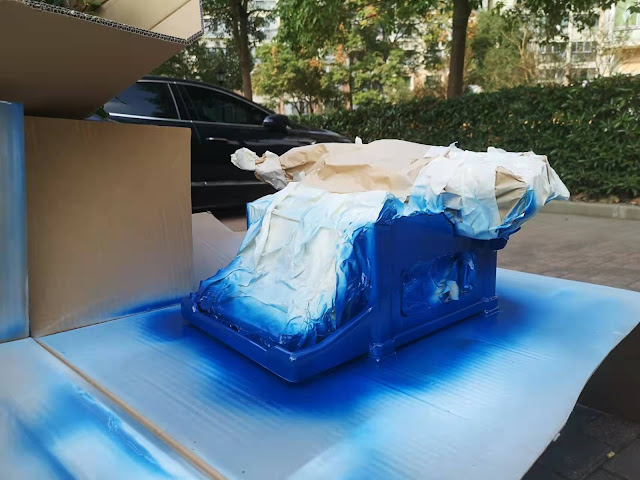

I bought this one from a local antique dealer. But to my disappointment, it wasn't working properly. The problem is that the rail on which the carriage moves is fractured. As I could not find any help back then, I simply glued the broken metal by silica gel. It actually worked, but barely passable. The carriage wobbles terribly whenever typed on, plus the platen had hardened up, making the whole typewriting not a satisfying experience. The real reason is because I didn't know how to take off the carriage. So I didn't have much options other than just inject some silica gel to fill up the fracture.

About half a year ago, I found the navy service manual of old typewriters. It did mention how to take off the carriage. But I didn't dare to try it on Royal 10 until quite recently . I have successfully restored some other typewriters recently. Obviously, these successes greatly emboldened me.

The whole process was very smooth. I did everything according to the service manual. After taking off the carriage, a friend of mine, who is a mechanic, welded the broken metal. It looks like new again!

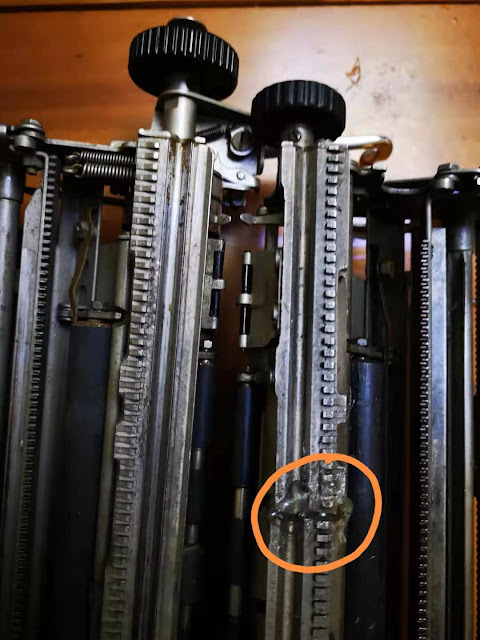

Then a new problem crops up. I dont know how to adjust the five clamps. The service manual didn't elaborate on the clamps, let's say, any theories needed to understand the function of the clamps other than just stablize the carriage. I need to figure out how to adjust the clamps.

I might need your help. Any idea on how to position these screws? Should they be in the middle of the slots as shown in this picture, or the upper, or lower positions? The carriage stuck terribly if the clamps are not properly adjusted.

Thank you.